Blog

Day 7: First firn air samples collected!!!

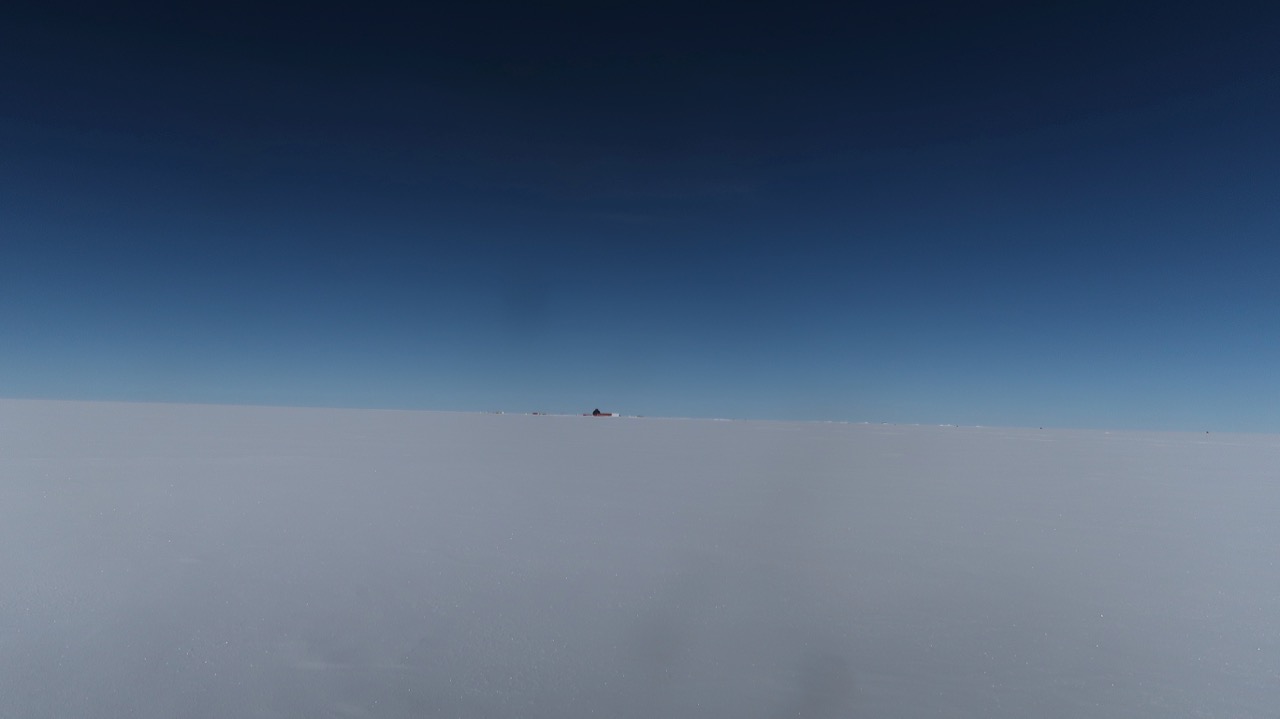

Fortunately I had quite a good night after the exhausting day yesterday. Well, I did wake up at 2 am and needed to go to the toilet, which is not particularly nice when it is -23ºC outside (-30ºC with windchill) because the toilet is in a small tent outside…. But after that I really slept well until 8:15! I had not even woken up when Johannes and Thomas in my tent got up (around 7) and they were already prepared to leave for the firn air site when I arrived for breakfast. It was not too bad since we still did not have power when they started. Fortunately Chris, the main technician moved our generator later in the morning and we finally had power. The firn air camp is now pretty much set up and looks beautiful not only from close-by but also from far away, then you get an impression how remote this location really is.

As soon as we had power we could finally start and test our instruments. It went relatively quick since everything was setup already, and after solving several problems we had the systems set up and tested. We also prepared the sampling lines, 3 tubes, each 110 m long, fixed them together and placed them on the snow behind our tent. We turned on the pumps and compressors and measured the total air flow rate that we can pump with our big compressors through the main sampling line, and it is about 15 liters per minute. At the end of the morning we were ready to collect samples and we were excited because the drilling would be gin in the afternoon.

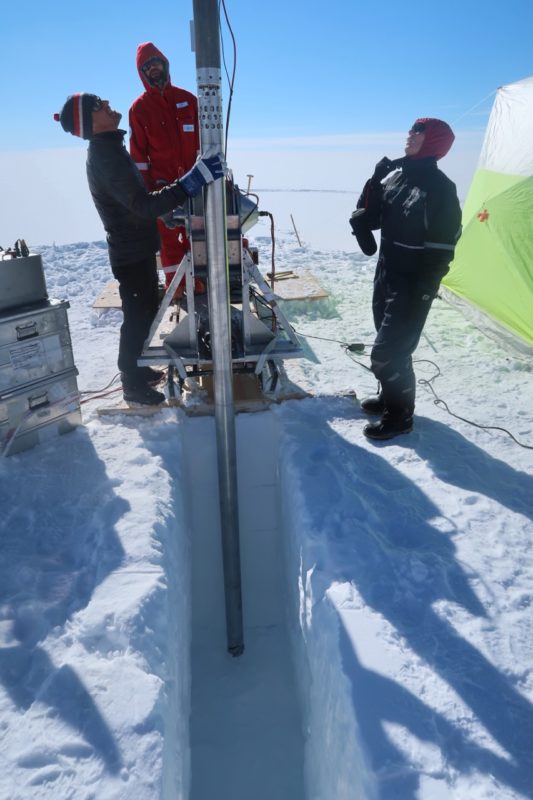

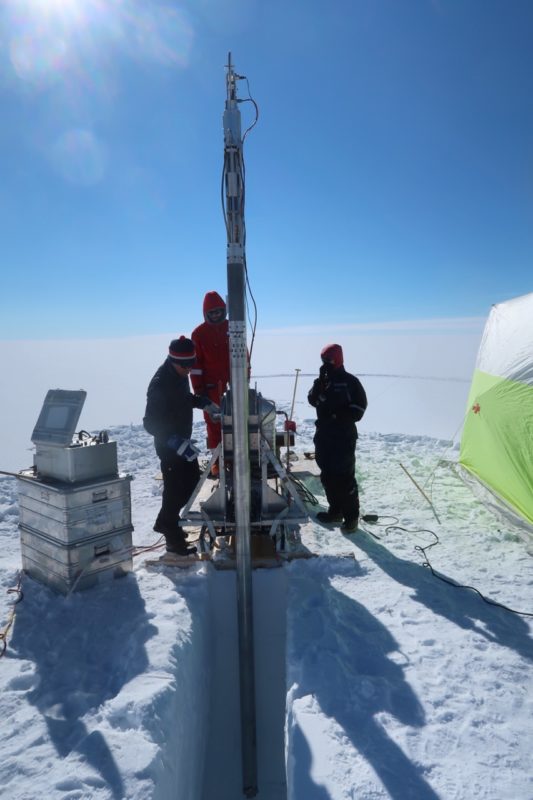

This is a good moment to introduce the firn air team. Here we are, during a break in the main dome, looking quite happy! From left right, we have Thomas (Blunier), a Swiss National working in Denmark, Camilla, a Danish National working in Switzerland, myself, Johannes from the Alfred Wegener Institute (AWI) in Germany, Ji-Woong from Korea and Kevin from France.  After lunch, Trevor, the head of the drilling operations in the EGRIP camp came with us and introduced our two drillers Johannes and Camilla to the drill that we will be using. The drill had to be tested and adjusted perfectly. It was then lowered into the trench that I dug together with Johannes yesterday about 2 m below the surface. Then the big moment had arrived and we started drilling the 2018 EGRIP firn air hole!

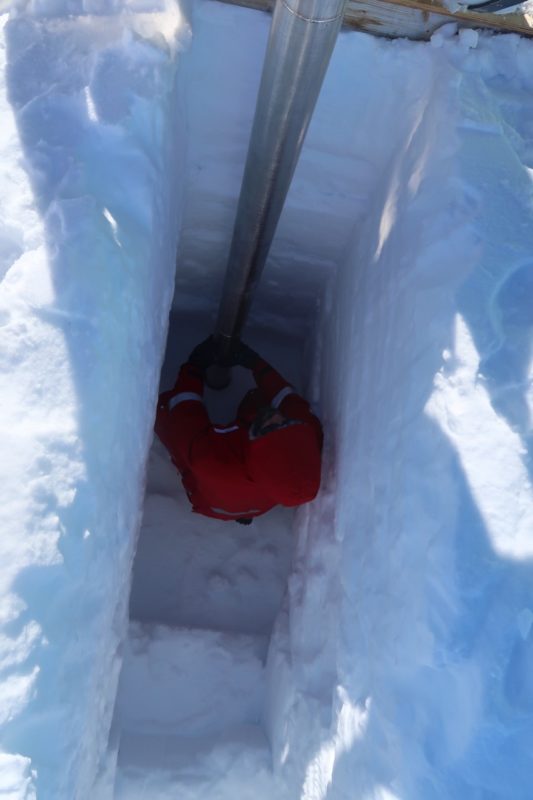

After lunch, Trevor, the head of the drilling operations in the EGRIP camp came with us and introduced our two drillers Johannes and Camilla to the drill that we will be using. The drill had to be tested and adjusted perfectly. It was then lowered into the trench that I dug together with Johannes yesterday about 2 m below the surface. Then the big moment had arrived and we started drilling the 2018 EGRIP firn air hole!

This is how the our first hole looks, well, not very spectacular, but it is a great step for us! And if you look closely you can that after the first run one piece of the core was actually left behind in the hole and the drillers had to lower the drill again to retrieve it.

In total, the drillers retrieved the first 3 m of firn core, in 7-8 pieces since the top firn is so fragile and breaks easily. So we are now in total 5 m below the surface, 2 m from the trench, plus 3 m from the drill hole. This is the depth where we wanted to take the first air samples. We logged the core accurately (noted the precise length, where the core is broken, scratches on the outside, etc.) and cut it in precisely 1 m pieces that were packed in bags and stored in boxes. These boxes will later be sent to the AWI in Germany for analysis (and some pieces also to other institutes). I have no photos today on this today since I was myself very much busy with this.

In total, the drillers retrieved the first 3 m of firn core, in 7-8 pieces since the top firn is so fragile and breaks easily. So we are now in total 5 m below the surface, 2 m from the trench, plus 3 m from the drill hole. This is the depth where we wanted to take the first air samples. We logged the core accurately (noted the precise length, where the core is broken, scratches on the outside, etc.) and cut it in precisely 1 m pieces that were packed in bags and stored in boxes. These boxes will later be sent to the AWI in Germany for analysis (and some pieces also to other institutes). I have no photos today on this today since I was myself very much busy with this.

Then we lowered the 3 m long bladder into the hole and inflated it so that the bladder sealed against the wall of the hole. And then another big moment had arrived, we could extract the first samples from below the bladder. The first canisters that we filled was actually one from our institute IMAU, a 6 L volume canister. Of course I was proud to have the first canister filled!

The normal canisters are filled here to 2 atmospheres above ambient pressure (which is about 750 mb, since we are at an altitude of 2700 m), so the canisters will have a final pressure of 2.75 bar. We filled in total 6 canisters from 6 different institutes today. It all was a bit slow, since each canisters has to be evacuated and then flushed with the firn air 2 times to make sure it is really clean and the previous air has been removed. This takes about 20 minutes per canister…. Also, we have different kinds of cylinders that have different connections and filling procedures, so it took quite some time (and we missed dinner by 2 hours). But it is good that we now have gone through the procedures once and we hope that tomorrow we can drill to the next level (maybe even two) and fill more canisters.